Liquid Feeding Control System

Overview

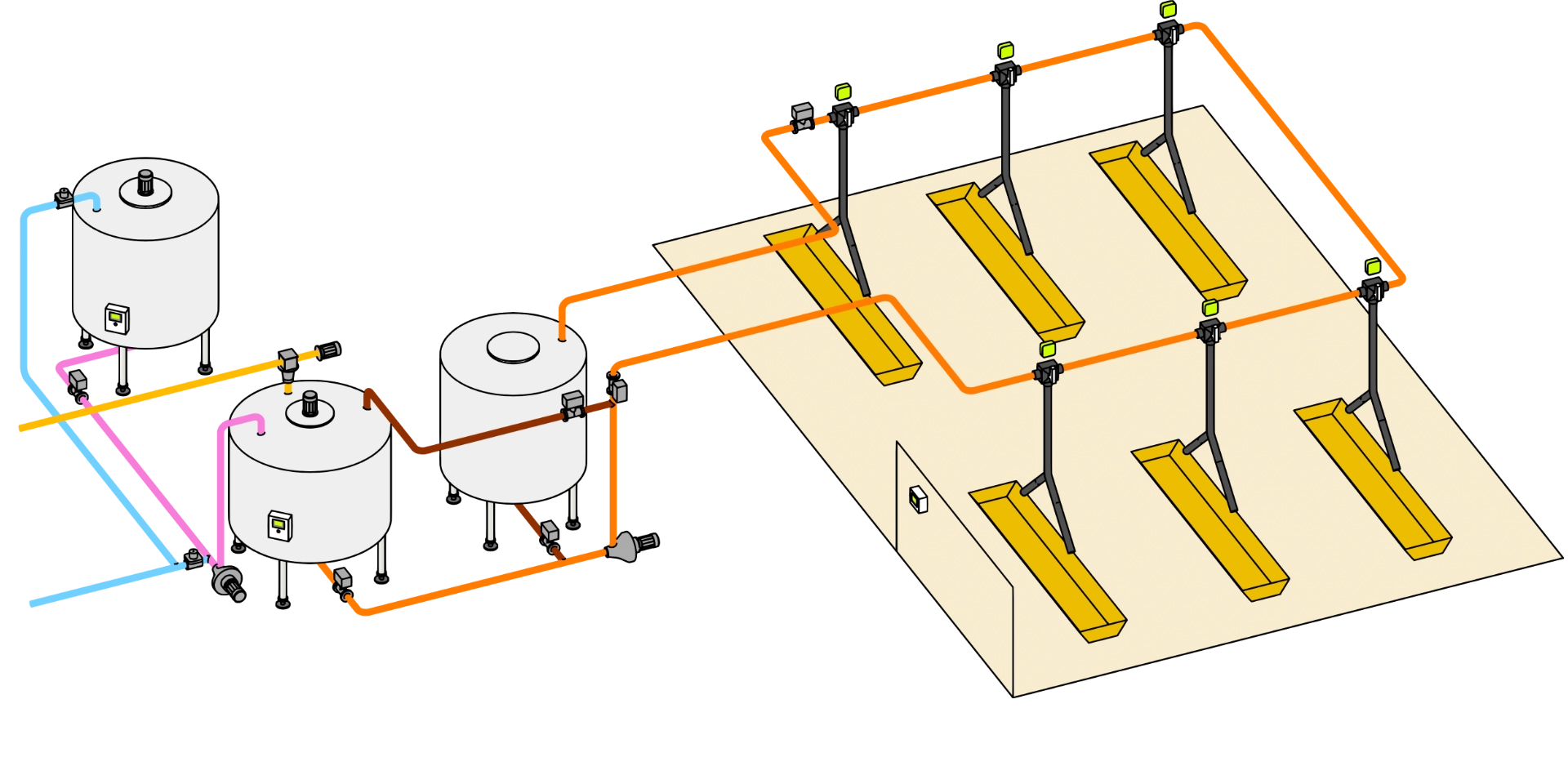

Our liquid feeding control system supports fully automated batching and feeding processes, seamlessly integrating fermentation, batching, and in-house delivery. The system is built on a modular and distributed control architecture, enabling precise management of feed preparation and distribution while minimizing operational complexity.

Each stage of the feeding cycle is monitored and controlled in real-time. The system features built-in IoT capabilities, allowing users to access operational data, diagnostics, and historical records via local touchscreens or remote cloud platforms.

Fermentation

Controller

Batching

Controller

Unit

Controller

Valve Control

Terminal

1. Fermentation Controller

Automated Feed Preparation

Key Features

- Manages the entire fermentation process automatically based on time or pH settings.

- Supports connection to weight sensors, level switches, pH/temperature sensors, and heaters.

- Syncs with the batching controller via PN communication.

- IoT-enabled for complete monitoring and traceability through HMI and cloud platforms.

Key Features

- Manages the entire fermentation process automatically based on time or pH settings.

- Supports connection to weight sensors, level switches, pH/temperature sensors, and heaters.

- Syncs with the batching controller via PN communication.

- IoT-enabled for complete monitoring and traceability through HMI and cloud platforms.

2. Batching Controller

Central Control Hub

Secondary silo controllers manage the distribution of feed from intermediate silos to downstream feed lines, supporting configurations where a single silo supplies multiple livestock farming units. Features include:

Key Features

- Functions as the system's master controller, managing batching, feeding, and cleaning processes.

- Enables one-touch automatic batching and delivery to multiple housing units.

- Compatible with a wide range of sensors and actuators for precise control.

- Provides centralized data visualization via touchscreens and cloud access.

- Coordinates directly with fermentation and unit-level controllers via PN communication.

3. Unit Controller

In-House Feed Distribution

Unit feed line controllers are designed to manage feed delivery within individual livestock farming units. Users can set specific feed quantities and schedules, with the system automatically initiating and terminating feeding cycles based on target withdrawal amounts. In configurations with hierarchical feed lines, the unit controller communicates with the corresponding silo controller to coordinate feeding processes. Key features include:

Key Features

- Automates the operation of feed valves within livestock housing units.

- Supports up to 40 valve channels per controller.

- Equipped with pneumatic pressure sensors to monitor system integrity.

- Integrates with the central batching controller to execute feeding commands.

- IoT-enabled for real-time monitoring and historical data tracking.

4. Valve Control Terminal

Localized Valve Management

The three-way valve controller regulates the direction of feed flow within the feed line system, allowing feed to either continue along the line or be diverted into specific silos. Features include:

Key Features

- Installed within livestock units for direct control of feed valves.

- IP65-rated for protection in harsh farm environments.

- Communicates with unit controllers to execute valve operations and report status.

- Reduces wiring complexity and maintenance costs through decentralized control.

- Includes onboard differential pressure sensors for local diagnostics.