Dry Feeding Control System

Overview

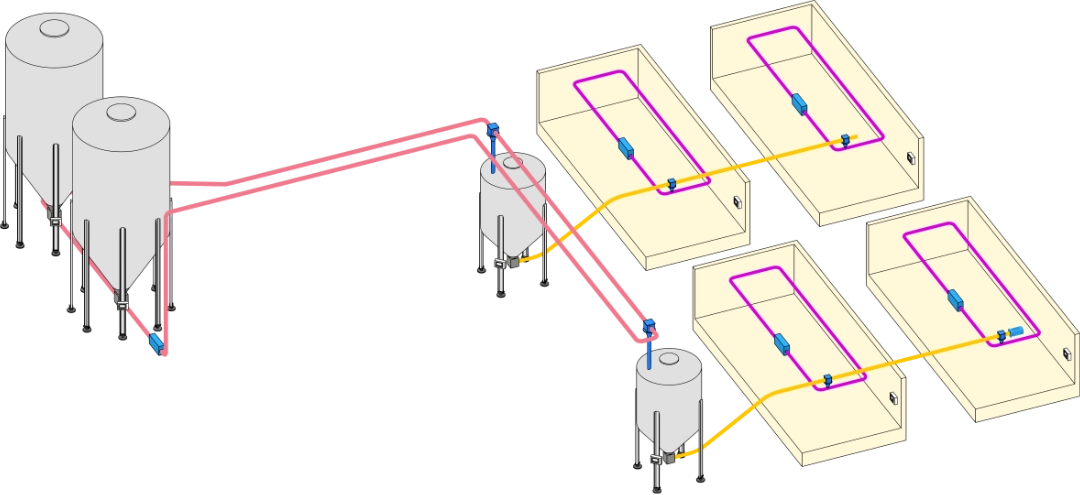

Our dry feeding control system offers a modular and scalable solution tailored for modern pig and poultry farming operations. Utilizing distributed PLC architecture, it efficiently manages multiple primary and secondary feed lines, intermediate silos, and relay feeding requirements. Integrated IoT-enabled touch-screen HMIs connect directly to digital load cells, eliminating the need for separate weighing indicators. This setup allows for real-time monitoring of feed intake and usage statistics via both the HMI and cloud-based platforms, enhancing operational transparency and efficiency.

Master

Controller

Silo

Controllers

Unit

Controllers

Valve Controllers

1. Master Controller

for Centralized Feed Distribution

The master controller serves as the central hub for orchestrating feed distribution from up to six primary silos to various secondary silos. Key features include:

Key Features

- Support for dual feed lines and multiple silo configurations.

- User-defined selection of source and destination silos with target feed quantities, enabling one-touch automated feeding cycles.

- Three operational modes: Automatic, Manual, and Manual Override.

- Real-time monitoring of primary silo inventory, discharge valves, vibratory motors, and feed line statuses.

- Real-time insights into secondary silo levels, feed requirements, communication statuses, and three-way valve positions.

- Compatibility with our digital weighing sensors or weighing indicators.

- Built-in IoT capabilities for data access via our IoT platform and on-site touchscreens.

2. Secondary Silo Controllers

for Downstream Feed Management

Secondary silo controllers manage the distribution of feed from intermediate silos to downstream feed lines, supporting configurations where a single silo supplies multiple livestock farming units. Features include:

Key Features

- Real-time monitoring of silo inventory, motor operations, feed line statuses, and feed level indicators.

- Support for both automatic and manual control of feed lines, three-way valves, discharge valves, and vibratory motors.

- Integration with our digital weighing sensors or weighing indicators.

- Communication capabilities with upstream master controllers and downstream unit-level controllers, forming a multi-tiered distributed feeding network.

- Built-in IoT functionalities for data access via our IoT platform and on-site touchscreens.

3. Unit Feed Line Controllers

for Individual Housing Units

Unit feed line controllers are designed to manage feed delivery within individual livestock farming units. Users can set specific feed quantities and schedules, with the system automatically initiating and terminating feeding cycles based on target withdrawal amounts. In configurations with hierarchical feed lines, the unit controller communicates with the corresponding silo controller to coordinate feeding processes. Key features include:

Key Features

- Control over feed boots and feed lines, with options for weight-based dispensing.

- Three operational modes: Automatic, Manual, and Manual Override.

- Compatibility with our digital weighing sensors or weighing indicators.

- Integration with upstream master controllers for cohesive distributed feeding operations.

- Built-in IoT capabilities for data access via our IoT platform and on-site touchscreens.

4. Three-Way Valve Controllers

for Feed Direction Management

The three-way valve controller regulates the direction of feed flow within the feed line system, allowing feed to either continue along the line or be diverted into specific silos. Features include:

Key Features

- Compatibility with various three-way valve types, enabling full automation when integrated with upstream control systems.

- Remote control and status monitoring via mobile devices.

- CAN bus communication for easy wiring and reduced control points.

- Low-voltage operation to mitigate voltage drop issues.

- Optional expansion for weighing functionalities.

- Integration into distributed feeding systems to minimize on-site cabling requirements.